- +91 9157153198

- info@shivshaktimachtech.com

- Kathwada, Gujarat 382430

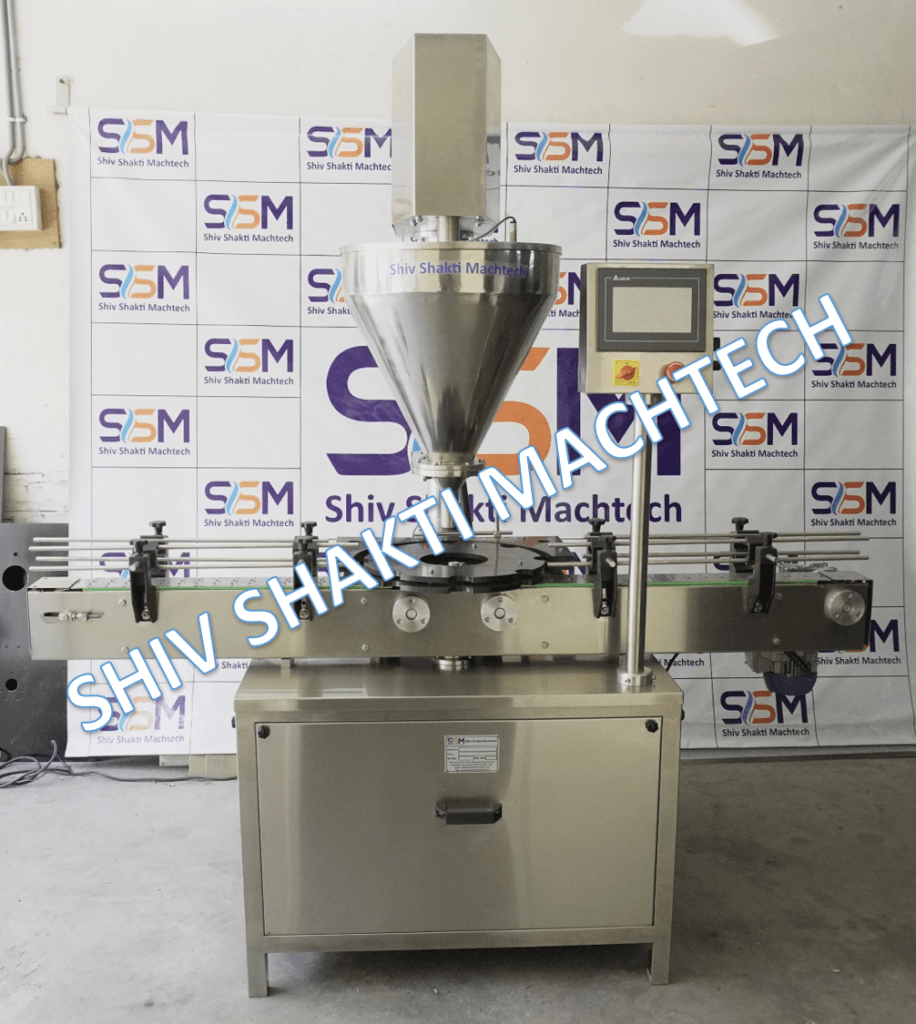

Home » Powder Filling Machine » Automatic Single Head Auger Type Powder Filling Machine

Automatic Single head Auger Type Powder Filling Machine is user friendly and highly market demand in industries for product line, Our reliable with Heavy duty built making machine, Automatic Single head Auger Type Powder Filling Machine are use friendly of wide different industry. Auger filling machine wide variety of standard to custom auger screw tooling accessories.

Shiv Shakti Machtech in Offering Complete Liquid Processing & Liquid Packaging Solutions to Segments Like Beverages, Chemicals, Cosmetics, Dairy, Detergents, Distilleries, Edible Oil, Fertilizers, Food, Nutraceuticals, Paints, Pharmaceutical, Lubricants Oil, Pesticides, Pigments, Plastics, and Other Liquid-based Manufacturing Industries.

The powder filling machine is mainly used for quantitative filling food, chemical, agricultural, building powders such as flour, milk powder, soy milk powder, protein powder, spices, enzymes, powder feed, enzymes, talc powder, asafoetida (hing), pesticides, metal powder, iron powder, facial mask powder, tooth powder, pharmaceutical powder, and other products.

Automatic Powder Filling Machine works on the principle of positive displacement of screw. Precisely designed auger is displaced product through funnel and container convey by conveyor belt. Empty bottles are fed through turn table /unscrambler/Airjet cleaning to conveyor belt of powder filling machine and flat conveyer feeding bottles to filling head on sets speed and bottles stop and hold for filling station. Sensor gives signal to servo motor start to rotate auger for filling. It will fill desire quantity of powder in to the container through auger. Powder filling machine precisely sets on desire requirement by timer controls and speed of auger can be set by variable speed drives. After filling of bottle pneumatic cylinder unhold bottles and move forward to further process on conveyor.

Auger type Powder Bottle Filling Machine Manufacturer in Kathwada, Ahmedabad, Gujarat, India and supplier in Vadodara, Vatva, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Daman, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Nasik, Pune, Rajasthan, Jaipur, , Udaipur, Kota, Bharatpur, Panoli, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, HP, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Kanpur, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Guwahati, Dibrugarh, Silchar, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Cuttack, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Vijayawada, Anantapur, Rajamahendravaram, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamilnadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Akola, Bhiwandi, Ahmednagar, Achalpur, Dhule, Latur, Chandrapur, Parbhani, Panvel, Yavatmal, Satara, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Sangli Miraj Kupwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli, Begusarai, Bapatla, Muzaffarnagar, Gorakhpur, Attur, Bengaluru

| Brand | SSM |

| Model No | AF-40 |

| Number of Head | 1 no |

| Speed* | Up to 30 bottles per minute |

| Power | 1.5 HP |

| Hopper Capacity | Approx. 25 liters |

| Suitable for Products | Free Flow Powder |

| Filling Range | 5ml to 1000ml with help of change parts |

| Direction of Movement | Left of Right |

| Filling Accuracy | 100g: ≤±2%, |

| ≥100 to 500g: ≤±1%, | |

| ≥500g to 1000gm: ≤±0.5% | |

| Working Principle | Volumetric |

| Bottle Stopper | Pneumatic Based |

| Height of Conveyor | 850mm (+50mm Adjustable) |

| Electrical Supply | 220 Volts, 1 Phase, 50 Hz. |

WhatsApp us