- +91 9157153198

- info@shivshaktimachtech.com

- Kathwada, Gujarat 382430

Home » Shrink Sleeve Label Applicators » Shrink Sleeve Label Applicator with Electric Tunnel

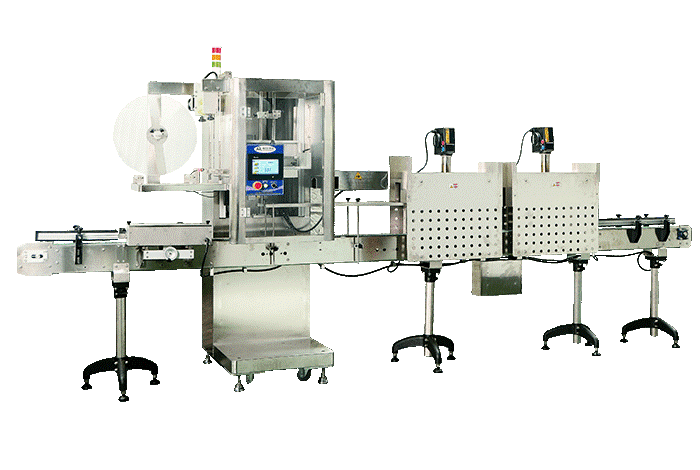

Shiv Shakti Machtech’s Shrink Sleeve Label Applicator with Electric Tunnel boasts cutting-edge technology for efficient labeling in packaging processes. Designed to meet the demands of modern production lines, this system offers precise application of shrink sleeve labels onto various containers, ensuring a sleek and professional finish. Equipped with two electric tunnels, the applicator guarantees uniform and consistent shrinking of the sleeves, enhancing the aesthetic appeal of the packaged products.

Shiv Shakti Machtech in Offering Complete Liquid Processing & Liquid Packaging Solutions to Segments Like Beverages, Chemicals, Cosmetics, Dairy, Detergents, Distilleries, Edible Oil, Fertilizers, Food, Nutraceuticals, Paints, Pharmaceutical, Lubricants Oil, Pesticides, Pigments, Plastics, and Other Liquid-based Manufacturing Industries.

The application process begins as containers move along the conveyor belt, guided by the applicator’s advanced sensors. As they reach the labeling station, the applicator precisely positions and applies the shrink sleeve labels with speed and accuracy. Simultaneously, the containers pass through the electric tunnels, where controlled heat is applied to shrink the sleeves securely around them. This dual-tunnel configuration ensures optimal shrinkage even for irregularly shaped or sized containers, maximizing the efficiency of the labeling process.

Operation of the Shrink Sleeve Label Applicator with Electric Tunnel is intuitive and user-friendly, thanks to its user-friendly interface and programmable settings. Operators can easily adjust parameters such as label size, shrinkage intensity, and conveyor speed to suit specific packaging requirements. Additionally, the system’s robust construction and reliable components minimize downtime, contributing to uninterrupted production cycles. With Shiv Shakti Machtech’s innovative solution, businesses can streamline their labeling processes and elevate the visual appeal of their products, ultimately enhancing brand recognition and consumer satisfaction.

| Brand | SSM |

|---|---|

| Model Number | SS-120 |

| Number of Head | 1 |

| Speed* | Up to 120 bottle per minute (depends on label length, bottle material and diameter of bottle) |

| Suitable for Products | Glass, plastic, PP, Pet, HDPE, LDPE, aluminum, metal Container |

| Shape of Container | Cylindrical / Square / Rectangle / Oval |

| Direction of Movement | Left of Right |

| Type | Full Body Sleeve / Middle Part Sleeve / Bottom Sleeve |

| Suitable Products | Empty Container / Filled Containers |

| Sleeve Roll Specification | External Diameter: 400mm |

| Core Diameter: 75mm | |

| Container sizes (With help of change parts) | Diameter: 30mm to 120mm |

| Height: 50mm to 250mm | |

| Sleeve (With help of change parts) | Length: 30 mm to 100 mm |

| Width: 40 mm to 170 mm | |

| Sleeve Material | OPS & PVC with 40 to 50 micron & 55% shrink ratio |

| Tunnel Material | Stainless Steel |

| Tunnel Type | Electric |

| Height of Conveyor | 850mm (+50mm Adjustable) |

| Electrical Supply | 220 Volts, 1 Phase, 50 Hz. |

WhatsApp us